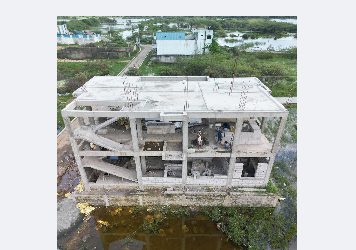

Building Dreams: Soulful Creators’ Latest Construction in Avadi, Chennai

Soulful Creators takes immense pride in presenting one of our most ambitious and thoughtfully designed projects—a 4 BHK duplex individual house in the vibrant locality of Avadi, Chennai. This two-floor modern marvel is not just a residence; it is a reflection of comfort, quality, and meticulous craftsmanship. Currently, the house has reached its cement construction stage, with final touches like plastering, painting, and plumbing works in the pipeline. Let us walk you through the journey of creating this dream home, right from its foundation to its near-completion status.

Foundation: Building a Strong Base

A sturdy house begins with a solid foundation, and for this 4 BHK duplex home, we laid a 6-foot-deep foundation. This depth was carefully calculated to ensure durability, considering the soil conditions of Avadi and the weight of the structure. The foundation involved:

1. Excavation and Soil Testing: Proper excavation ensured the soil was suitable for load-bearing. We conducted detailed tests to determine soil stability.

2. PCC (Plain Cement Concrete): A robust PCC layer provided a leveled base and prevented direct contact between soil and the foundation footing.

3. Reinforcement Barring Work: High-grade TMT bars were used for the foundation’s reinforcement, ensuring resistance against tension and compression.

4. Concrete Pouring: The concrete mix was a precise combination of cement, sand, aggregates, and water, achieving the desired strength.

5. Curing: Post-concreting, curing was carried out diligently for 21 days to ensure the concrete gained optimum strength.

Soulful Creators has always prioritized quality, sustainability, and customer satisfaction.

Structural Framework: Strengthening the Skeleton

Once the foundation was complete, the focus shifted to erecting the structural framework, the skeleton of the house. This included columns, beams, and slabs.

Column and Beam Construction: Carefully designed RCC columns and beams were installed to provide strength and stability. The steel bars used in reinforcement adhered to IS codes, ensuring safety and longevity.

Roofing and Slab Work: For the roofing, we used high-quality steel bars in the reinforcement grid. Concrete slabs were poured over the grid, ensuring even distribution of load and creating a durable roof structure. The roofing process involved:

Double-layer steel bar work for added strength.

Use of shuttering plates and supports to shape the slab during concreting.

Vibratory compactors to eliminate air gaps and achieve a flawless slab.

Brickwork and Walls: Adding Shape and Functionality

Brickwork followed the structural framework, giving shape to the house. We chose premium-grade bricks that provided thermal insulation and strength. The walls were built with:

Accurate Mortar Mix: A consistent mix of cement and sand ensured strong bonding.

Straight and Plumb Alignment: Precision tools ensured the walls were perfectly aligned and plumb.

Curing of Brickwork: Post-construction, the walls were cured to prevent cracks and enhance durability.

Quality Cement: The Heart of Construction

Cement plays a crucial role in the construction process. For this project, we opted for high-grade cement that provides excellent binding properties and ensures longevity. Quality checks were performed to:

Verify the fineness and consistency of the cement.

Ensure the cement was free of lumps and had a uniform color.

Confirm its setting time and strength were optimal for each stage of construction.

Barring Work: Ensuring Robust Support

Reinforcement barring work was a critical aspect of this project. For both the foundation and roofing, we:

Used corrosion-resistant TMT bars for durability.

Maintained proper spacing and overlapping in the bar grid to ensure uniform load distribution.

Conducted periodic inspections to verify the alignment and fix any discrepancies.

Curing: A Key to Longevity

Curing was given utmost importance throughout the construction process. Proper curing prevents cracks, enhances strength, and improves durability. Whether it was the foundation, columns, beams, or walls, curing was carried out diligently for the prescribed durations.

Future-Proof Design: Maximizing Space and Utility

This duplex house is designed with foresight, considering future expansion and the optimal use of available space. The layout includes:

A spacious living area and modular kitchen on the ground floor.

Well-ventilated bedrooms with attached bathrooms.

A dedicated family lounge and balcony on the first floor.

Provision for solar panels and rainwater harvesting to promote sustainability.

A well-planned staircase that connects the floors seamlessly.

Next Steps: Final Touches for a Perfect Home

With the cement construction completed, the next phase involves:

Plastering: Smoothening and leveling the walls and ceilings.

Painting: Applying weatherproof and aesthetic finishes to interiors and exteriors.

Plumbing and Electrical Work: Installing modern fixtures and fittings to enhance functionality and comfort.

Flooring: Laying durable and visually appealing tiles or marble.

Conclusion: A Home That Reflects Excellence

Soulful Creators has always prioritized quality, sustainability, and customer satisfaction. This 4 BHK duplex house in Avadi is a testament to our dedication and expertise. As we near the completion of this project, we envision a home that not only meets but exceeds the expectations of its future occupants. Stay tuned as we bring this dream home to life, brick by brick, with passion and precision.